English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

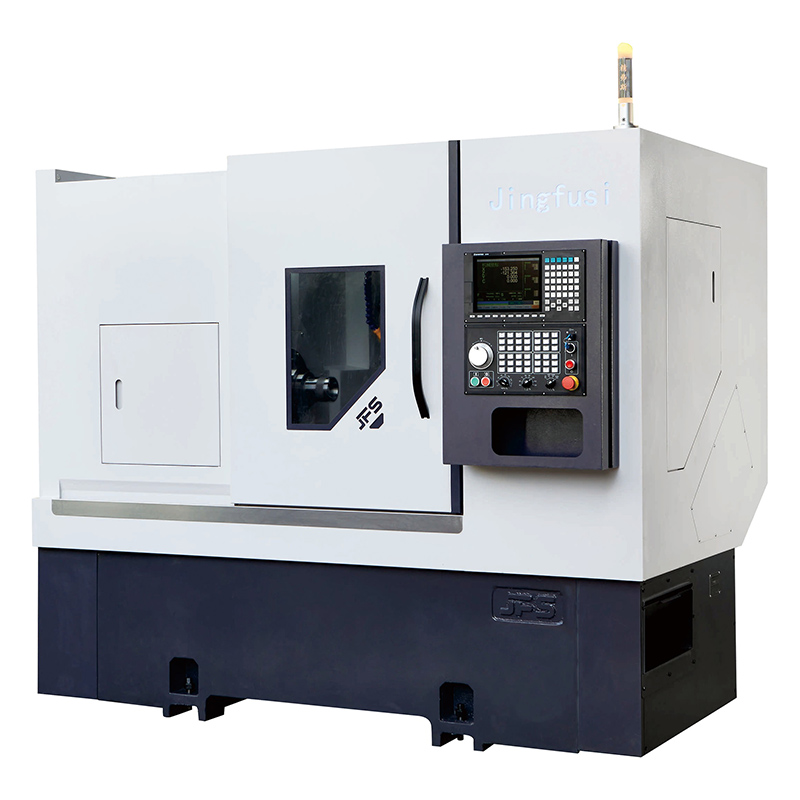

Power Turret CNC Lathe CK46 52DTY

Send Inquiry

As a manufacturer, Jingfusi provides high-quality Power Turret CNC Lathe CK46 52DTY.

Product Feature

Under the premise of completely consistent configuration, casting structure, aging treatment and assembly accuracy, virtual Y axis and vertical Y axis have their own advantages: virtual Y axis is more rigid, and roundness adjustment is more convenient; vertical Y axis is more flexible in stroke extension, and the machined workpiece surface finish is also better. At the same time, programming operation is simpler than virtual Y axis.

In addition, the equipment also has these practical highlights: 0° power head can achieve stable operation of 8000 RPM, 90° power head rated working speed of 6500 RPM; tool holder adopts gearless module transmission design, eliminating the influence of heat source from the root, which can effectively guarantee machining accuracy; milling and turning functions are integrated, which can easily meet the machining requirements of complex materials such as stainless steel, titanium alloy and carbon steel; Chip removal system adopts side + back integrated design, flexible installation mode, can be arbitrarily selected according to actual working conditions.

In addition, the whole machine castings are subjected to annealing, vibration aging and other multi-channel aging treatment processes, which can not only ensure the stability in the long-term processing process, but also effectively extend the service life of the equipment.

Main Specification

| Model of lathe | unit | CK52DTYW-500 | CK76DTYW-500 | Remart | |

| Processing capacity | Max swing diameter over bed | mm | 0700 | Ø700 |

|

| Maximum tumning diameter | mm | 0230 | Ø230 |

|

|

| Max.turning length | mm | 500 | 500 |

|

|

| Spindle | spindle hydraulic chuck | in | 8" | 10" |

|

| Spindle center height fom ground | mm | 1150 | 1150 |

|

|

| Spindle nose |

|

A2-6 | A2-8 |

|

|

| Spindle bore diameter | mm | Q66 | 086 |

|

|

| Maximum bar mateia diameter | mm | Ø51 | 072 |

|

|

| Maximum spindle speed | r/min | 4000 | 2000 |

|

|

| Spindle motor power/ torque | Kw/N.m | 11Kw/72N.m | 15Kw/143N.m | Optional integrated 11kW/60Nm/ Optional integrated 22kW/170Nm | |

| Power Turret | Power turret model | - | BMT55-16Tor BMT55-12T | BMT55-16Tor BMT55-12T | Taiwan GPM servo-powered turret, formerly German SAUTER brand. |

| Turret motor power/torque | Kw/N.m | 5.7Kw/18N.m or 3.1KW/15Nm | 5.7Kw/18N.m or 3.1KW/15Nm |

|

|

| Power ture tolmax speed | r/mm | 5000 | 5000 | °can be operated at 8000 RPM,and 90°can be operated at 6500 RPM. | |

| X/Z/Y axis feeding | ×Z axis Max.fast tavel speed | m/min | 24 | 24 |

|

| Yaxis Max.fast travel speed | m/min | 15 | 15 |

|

|

| X/Z/Y-axis motor power/torque | Kw/N.m | YASKAWAI 29KW/186Nm or SYTEC 3.1KW/15Nm | YASKAWA 29KW/186Nm or SYMTEC 3.1 KW/15Nm |

|

|

| XZY-xis C3-grade ball srews | - | 40/40/40 | 40/40/40 |

|

|

| XZY-axis rller guide rails | - | 35/45/35 | 35/45/35 |

|

|

| Xaxis effective travel | mm | 250 | 250 |

|

|

| Z axis effective travel | mm | 500 | 500 |

|

|

| Y axis effective travel | mm | 112(±56) | 112(±56) |

|

|

| Bmaesthogh | mm | 50 | 50 | Based on the 70 center high-power tool holder | |

| Tailstock | Tailstock travel | mm | 520 | 520 | programed tailstock |

| Ejector pin taper hole | MK | Mo's 5# | Mo's 5# |

|

|

| Equipmentspecifications | Machine net weight | kg | 4500 | 4600 |

|

| Total machine power | KW | 26 | 30 |

|

|

| Machine L×W×H | mm | 2500×1680×1900 | 2500×1680×1900 |

|

|

The machine tool s constantly being optimized;please refer to the actual data of the machine tool for the above parameters.

Optional items

| Configuration item | CK52DTYW-500 | CK76DTYW-500 | |

| Main Spindle | Mechanical spindle | ● | ● |

| Electric spindle | O | O | |

| controller | SYNTEC controller | ● | ● |

| FANUC controller | O | O | |

| Feed axis | Yaskawa | ● | ● |

| SYNTEC | O | O | |

| Turret | BMT55 Power Turret | ● | ● |

| BMT55 Power Turret | 一 | O | |

| Tailstock | Morse#5 | O | O |

| Clamping | Pull back clamp | ● | ● |

| Chuck | O | O | |

| Auxiliary equipment | Parts collect device | O | O |

| Feeding device | O | O | |

| Chip conveyor | O | O | |

| Automated robot | O | O | |

| Oil mist separator | O | O | |

Standard configurationo O

ptional configuration ●

Not selectable_

Product intemal photo

Processing samples