English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

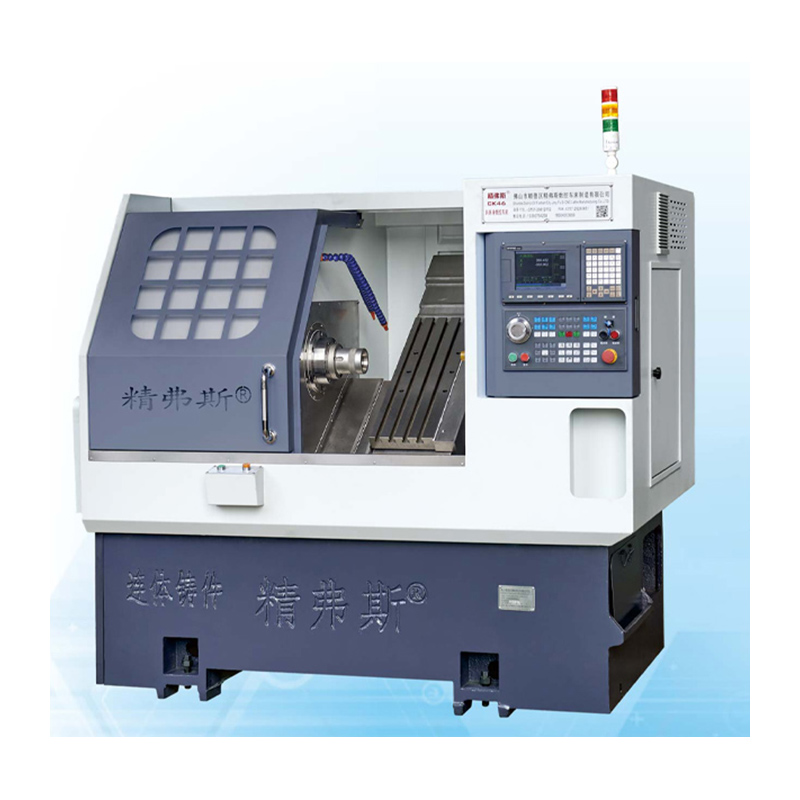

Slant Bed CNC Lathe Machine

The Jingfusi® slant bed CNC lathe machine is a type of computer numerical control (CNC) lathe that features a slanted or inclined bed design. This design distinguishes it from traditional flat bed lathes. In a slant bed lathe, the machine's bed or base is inclined at an angle, typically around 35 degrees, relative to the horizontal plane. This design offers several advantages and is commonly used in modern machining and manufacturing processes.

Model:CK46

Send Inquiry

Product Description

Jingfusi® is a leading China Slant Bed CNC Lathe Machine manufacturer, supplier and exporter. Adhering to the pursuit of perfect quality of products, so that our Slant Bed CNC Lathe Machine have been satisfied by many customers. Extreme design, quality raw materials, high performance and competitive price are what every customer wants, and that's also what we can offer you. Of course, also essential is our perfect after-sales service. If you are interested in our services, you can consult us now, we will reply to you in time!

Jingfusi® Slant Bed CNC Lathe Machine Features:

35 degrees slant bed CNC lathe

Chip conveying capacity is large and convenient, customer could choose chip conveying in the front or in the back

Screw pre-stretching structure

Gang type tool post

Chip conveying capacity is large and convenient, customer could choose chip conveying in the front or in the back

Screw pre-stretching structure

Gang type tool post

Here are some key features and benefits of a slant bed CNC lathe machine:

Rigidity: The slant bed design enhances the rigidity of the machine, providing better support and stability for cutting tools and workpieces. This rigidity results in improved machining accuracy and surface finish.

Chip Management: The slanted orientation of the bed allows for more effective chip evacuation. Chips produced during the machining process tend to fall away from the work area, reducing the risk of chip buildup and tool damage.

Ergonomics: Slant bed lathes often have a more ergonomic design, making it easier for operators to load and unload workpieces. The inclined bed provides better visibility of the machining area, which can improve operator efficiency and safety.

Reduced Tool Interference: The slant bed design reduces the risk of interference between the cutting tool and the workpiece, especially when machining complex or contoured parts.

High-Speed Machining: Slant bed lathes are well-suited for high-speed machining operations. The improved rigidity and chip evacuation capabilities allow for faster cutting speeds and higher productivity.

Versatility: These machines are versatile and can be used for a wide range of turning operations, including facing, turning, drilling, threading, and grooving.

Automation Integration: Slant bed CNC lathes can be easily integrated with automation systems, such as robotic loaders, to further enhance productivity and reduce manual labor.

Precision and Accuracy: The rigidity and stability of the slant bed design contribute to higher machining precision and accuracy, making it suitable for applications that require tight tolerances.

Material Compatibility: Slant bed lathes can handle a variety of materials, including metals, plastics, and composites, making them suitable for a broad range of industries, such as aerospace, automotive, and medical device manufacturing.

Tool Changes: Many slant bed CNC lathes are equipped with tool changers that allow for quick and automated tool changes, reducing downtime and increasing efficiency.

In summary, a slant bed CNC lathe machine offers several advantages over traditional flat bed lathes, including improved rigidity, chip management, and ergonomics. These machines are commonly used in modern machining environments where precision, efficiency, and versatility are essential.

Chip Management: The slanted orientation of the bed allows for more effective chip evacuation. Chips produced during the machining process tend to fall away from the work area, reducing the risk of chip buildup and tool damage.

Ergonomics: Slant bed lathes often have a more ergonomic design, making it easier for operators to load and unload workpieces. The inclined bed provides better visibility of the machining area, which can improve operator efficiency and safety.

Reduced Tool Interference: The slant bed design reduces the risk of interference between the cutting tool and the workpiece, especially when machining complex or contoured parts.

High-Speed Machining: Slant bed lathes are well-suited for high-speed machining operations. The improved rigidity and chip evacuation capabilities allow for faster cutting speeds and higher productivity.

Versatility: These machines are versatile and can be used for a wide range of turning operations, including facing, turning, drilling, threading, and grooving.

Automation Integration: Slant bed CNC lathes can be easily integrated with automation systems, such as robotic loaders, to further enhance productivity and reduce manual labor.

Precision and Accuracy: The rigidity and stability of the slant bed design contribute to higher machining precision and accuracy, making it suitable for applications that require tight tolerances.

Material Compatibility: Slant bed lathes can handle a variety of materials, including metals, plastics, and composites, making them suitable for a broad range of industries, such as aerospace, automotive, and medical device manufacturing.

Tool Changes: Many slant bed CNC lathes are equipped with tool changers that allow for quick and automated tool changes, reducing downtime and increasing efficiency.

In summary, a slant bed CNC lathe machine offers several advantages over traditional flat bed lathes, including improved rigidity, chip management, and ergonomics. These machines are commonly used in modern machining environments where precision, efficiency, and versatility are essential.

Machine Travel Diagram

Product Details

Parameter List

| project | unit | CK46 | CK52 | CK76 | |

| Maximum turning length | mm | 350 | |||

| Maximum turning diameter on the bed | mm | Ø 500 | |||

| Maximum turning diameter on the skateboard | mm | Ø 160 | |||

| Bed inclination | ° | 35° | |||

| Effective travel of X/Z axis | mm | Diameter 1000/400 | |||

| X/Z axis screw specifications | mm | 32 | |||

| X/Z axis rail specifications | mm | 35 | |||

| X/Z-axis motor power | KW | 1.3 | |||

| Maximum fast movement of X/Z axis | m/min | 24 | |||

| Machine tool length X width X height | mm | 2100X1580X1800 | |||

| Total weight of the entire machine | KG | 2600 | |||

| Knife number | fix | 8 | |||

| Square knife size | mm | 20X20 | |||

| Round hole cutter size | mm | Ø20 | |||

| Total power | kw | 13 | 13 | 16 | |

| Average power consumption | kw/h | 2 | 2 | 2.5 | |

| main shaft | Spindle end face form |

|

A2 - 5 | A2 - 6 | A2 -8 |

| Maximum spindle speed | r/min | 6000 (set to 4500) | 4200(set to 3500) | 3200(set to 2500) | |

| Spindle motor power | KW | 7.5 | 7.5 | 11 | |

| Rated torque of spindle motor | Nm | 47.8Nm | 47.8Nm | 72Nm | |

| Maximum bar passing diameter | mm | Ø 45 | Ø 51 | Ø 75 | |

Machine Tool Accuracy

| Machine accuracy,Jingfus factor standard : | ||||

| Major test item | Schematic diagram |

Detection method |

Factory standard |

|

| Spindle radial beat, |

|

Detect runout of outer cone | 0.0025 | |

| X-axis repeat position |

|

Detect repeated positioning of the X-axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.0025 | |

| Z-axis repeat position |

|

Detect repeated positioning on the Z axis. Note: First predict about 50 times to offset the error of the cold engine and hot engine, and then detect the repeated positioning. | 0.0025 | |

| If the customer wants to test the ISO or VD1 accuracy of X/Z/Y axis, it shall be determined at the time of writing the contract. The customer must test this item at the same time of the initial acceptance of Jingfusi Factory. | ||||

Hot Tags: Slant Bed CNC Lathe Machine, China, Manufacturers, Suppliers, Factory, Quality, Price List

Product Tag

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy