English

English-

English

English -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик -

Español

Español -

Português

Português

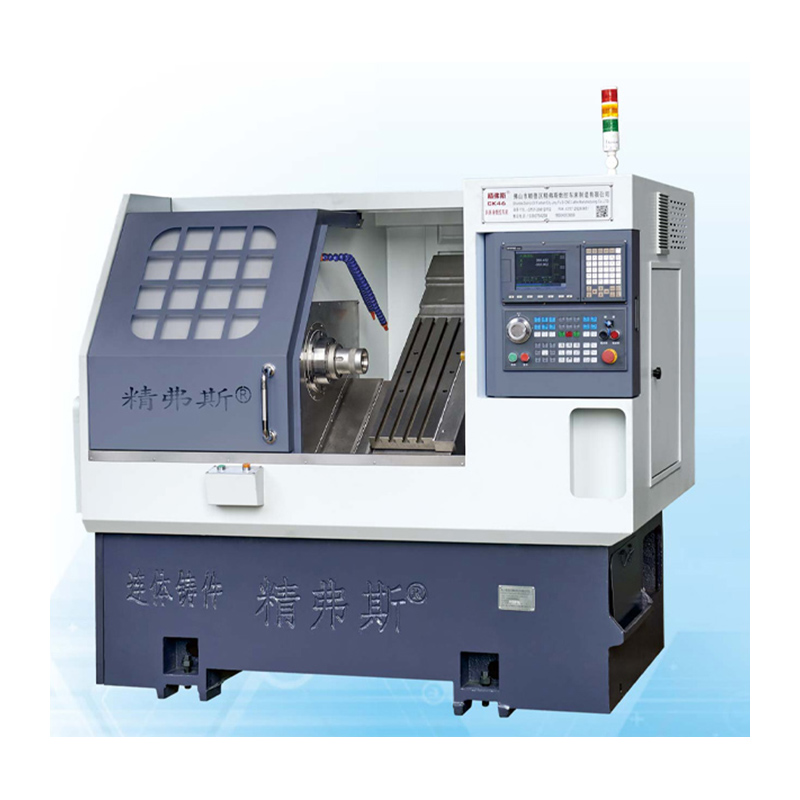

High Precision Slant Bed CNC Lathe

Send Inquiry

The High Precision Slant Bed CNC Lathe is a type of computer-controlled lathe machine that is designed for precision machining of workpieces. It is characterized by a slanted bed design, where the machine's bed is inclined at an angle, typically around 30 to 45 degrees. This slant bed design offers several advantages, including improved chip evacuation, better rigidity, and enhanced access to the workpiece. Here are key features and benefits of a High Precision Slant Bed CNC Lathe:

Slant Bed Design: The inclined bed provides better chip flow and easier removal of chips and coolant during the machining process. This design helps in maintaining a cleaner and more efficient workspace.

High Precision: These CNC lathes are known for their exceptional precision and accuracy in turning and machining workpieces. They can achieve tight tolerances and fine surface finishes.

Rigidity: The slant bed design enhances the machine's rigidity, resulting in improved cutting stability and reduced vibrations during high-speed machining.

Reduced Tool Wear: With the improved rigidity and stability, tool wear is minimized, leading to longer tool life and reduced maintenance costs.

Versatility: High Precision Slant Bed CNC Lathes can handle a wide range of materials, from metals like steel and aluminum to plastics and composites. This versatility makes them suitable for various industries.

Quick Tool Changes: Many Horizontal Flat Bed CNC Turning Lathe come equipped with automatic tool changers, enabling rapid tool changes during machining operations, saving time and improving efficiency.

Multi-Axis Control: These machines often feature multiple axes, allowing for complex part machining and the ability to create intricate geometries and features.

Tailstock and Live Tooling: Some models are equipped with a tailstock for additional support, and live tooling capabilities for milling and drilling operations, expanding their capabilities beyond traditional turning.

Operator-Friendly Interface: The CNC control system is typically user-friendly, with a graphical interface that allows operators to program and control the lathe with ease.

Production Efficiency: High Precision Slant Bed CNC Lathes are used in high-production environments where fast and accurate machining is required, making them valuable assets in industries like aerospace, automotive, and medical device manufacturing.

Batch and Single-Piece Production: These machines are suitable for both batch production and the machining of single, custom parts, making them versatile for various production scenarios.

Safety Features: Modern CNC lathes are equipped with safety features, such as emergency stop buttons and interlocks, to ensure the safety of operators.

Overall, a High Precision Slant Bed CNC Lathe is a valuable tool for manufacturers who require precise and efficient turning and machining operations. Their combination of rigidity, precision, and versatility makes them ideal for a wide range of applications in the manufacturing industry.

Horizontal Flat Bed CNC Turning Lathe Travel Diagram

Product Details

Parameter List

| project | unit | CK46 | CK52 | CK76 | |

| Maximum turning length | mm | 350 | |||

| Maximum turning diameter on the bed | mm | Ø 500 | |||

| Maximum turning diameter on the skateboard | mm | Ø 160 | |||

| Bed inclination | ° | 35° | |||

| Effective travel of X/Z axis | mm | Diameter 1000/400 | |||

| X/Z axis screw specifications | mm | 32 | |||

| X/Z axis rail specifications | mm | 35 | |||

| X/Z-axis motor power | KW | 1.3 | |||

| Maximum fast movement of X/Z axis | m/min | 24 | |||

| Machine tool length X width X height | mm | 2100X1580X1800 | |||

| Total weight of the entire machine | KG | 2600 | |||

| Knife number | fix | 8 | |||

| Square knife size | mm | 20X20 | |||

| Round hole cutter size | mm | Ø20 | |||

| Total power | kw | 13 | 13 | 16 | |

| Average power consumption | kw/h | 2 | 2 | 2.5 | |

| main shaft | Spindle end face form |

|

A2 - 5 | A2 - 6 | A2 -8 |

| Maximum spindle speed | r/min | 6000 (set to 4500) | 4200(set to 3500) | 3200(set to 2500) | |

| Spindle motor power | KW | 7.5 | 7.5 | 11 | |

| Rated torque of spindle motor | Nm | 47.8Nm | 47.8Nm | 72Nm | |

| Maximum bar passing diameter | mm | Ø 45 | Ø 51 | Ø 75 | |